VACUUM MACHINE SC-124V/IVP

Floor Line..New version with IVP - Intelligent Vacuum Packaging. High-resolution LCD display, color to display all vacuum phases .Standard with 2 seal bars: 1 x 760 (front), 1x 510 mm (right).

Manufacturer: DIAMOND

Available in:

2-3 days

Dimensions (mm):

910 x 740 x 1060

Power (kW):

3,5

Weight (kg):

273

Power supply:

400-230/3N 50Hz

Base price 9 360 €

Salesprice with discount

Sales price 11 326 €

Price / kg:

Product description

VACUUM MACHINE SC-124V/IVP

- Control panel with LCD display (IVP: INTELLIGENT VACUUM PACKAGING).

- Vacuum pump capacity 100 m3/h. (Busch type).

- Cycle time 15-40 seconds.

- Aluminium cover with window.

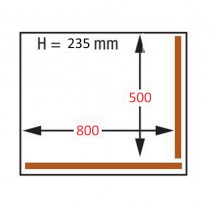

- Chamber dimensions: 800x500xh235 mm.

- Working height 900 mm.

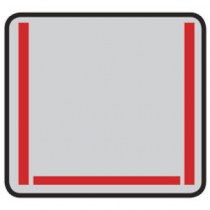

- 2 sealing bars.

- Digital control system with 10 programs.

- Soft air.

- Vacuum machine with innovative design, made entirely of AISI 304 stainless steel.

- Deep-drawn inner tank, made of AISI 304 stainless steel, easy to maintain, guaranteeing perfect hygiene.

- Removable sealing bar.

- Rigorous double welding of 3.5 mm.

- Large, high-resolution colour LCD display, allowing you to view all the steps of the vacuuming process.

- Programming directly on the machine keyboard or from a PC (Storage of 20 recipes or specific products), data transfer via USB port.

- The vacuum is managed in % or mbar thanks to the integrated vacuum sensor, no more risk of inadvertently incomplete vacuum.

- Possibility to assign a user code to each operator.

- All operations are stored in the chip of the electronic card and the "log book" of use can be exported to a PC, guaranteeing HACCP control and optimized management of all vacuum operations.

- The device is built in compliance with the current CE standards.

OPTIONS :

- IDG - Nitrogen gas injection system.

- 3BS - 3 sealing bars.

- RLS - Soft air slow return.

- PIL - Plate for liquid products.

- TSC - Welding with cut-off.

- LIQ: Liquid control sensor.

PLUS:

- The most advanced vacuum machines on the market.

- State-of-the-art, high-performance technology for the optimal use of the "vacuum kitchen".

- Here are some of the advantages of the I.V.P. control panel, with a large LCD colour display:

- Red meat function to avoid loss of exudate (Serous liquid).

- Sequential vacuum function specially developed for terrines, pattes, mousses etc... also very popular in pastry and bakery.

- Marinade function, specially developed to allow an even more intense infusion.

- Log book" of maintenance operations, automatic detection of possible malfunctions.

- 6 pre-programmed languages (Fr, Nl, De, It, En, Es, Ru,...)

- Many options on request, label printer, gas injection "Nitrogen", liquid control sensor,...

Related Products

SMOOTH VACUUM BAGS 150x300 mm A25-1530

25 packaging off 100 pieces."Smooth" vacuum bags for under machines with ...

Base price: 255 €

Salesprice with discount

Sales price 309 €

Price / kg:

SMOOTH VACUUM BAGS 200x300 mm A20-2030

20 packaging off 100 pieces."Smooth" vacuum bags for under machines with ...

Base price: 275 €

Salesprice with discount

Sales price 333 €

Price / kg:

SMOOTH VACUUM BAGS 250x350 mm A16-2535

16 packaging off 100 pieces."Smooth" vacuum bags for under machines with ...

Base price: 325 €

Salesprice with discount

Sales price 393 €

Price / kg:

SMOOTH VACUUM BAGS 300x400 mm A10-3040

10 packaging off 100 pieces."Smooth" vacuum bags for under machines with ...

Base price: 275 €

Salesprice with discount

Sales price 333 €

Price / kg:

SMOOTH VACUUM BAGS 400x500 mm A06-4050

6 packaging off 100 pieces."Smooth" vacuum bags for under machines with ...

Base price: 275 €

Salesprice with discount

Sales price 333 €

Price / kg:

COOKING VACUUM BAGS 150x300 mm C25-1530

25 packaging off 100 pieces."Smooth" cooking vacuum bags for machines with ...

Base price: 375 €

Salesprice with discount

Sales price 454 €

Price / kg:

COOKING VACUUM BAGS 200x300 mm C20-2030

20 packaging off 100 pieces."Smooth" cooking vacuum bags for machines with ...

Base price: 390 €

Salesprice with discount

Sales price 472 €

Price / kg:

COOKING VACUUM BAGS 250x350 mm C16-2535

16 packaging off 100 pieces."Smooth" cooking vacuum bags for machines with ...

Base price: 450 €

Salesprice with discount

Sales price 545 €

Price / kg:

COOKING VACUUM BAGS 300x400 mm C10-3040

10 packaging off 100 pieces."Smooth" cooking vacuum bags for machines with ...

Base price: 390 €

Salesprice with discount

Sales price 472 €

Price / kg:

TRIPLE WELDING 3BS/SC-124V/N

Base price: 825 €

Salesprice with discount

Sales price 998 €

Price / kg:

GAS INJECTION IDG/SC-124V/N

Base price: 627 €

Salesprice with discount

Sales price 759 €

Price / kg:

LIQUID CONTROL SENSOR / PRESSURE SENSOR (%) / 20 prog. LIQ/SC-124V/IVP

Base price: 330 €

Salesprice with discount

Sales price 399 €

Price / kg:

SIMPLE SOLDERING WITH CUT-OFF TSC/SC-124V/N

Base price: 28 €

Salesprice with discount

Sales price 34 €

Price / kg:

PLATE FOR LIQUID PRODUCTS PIL/SC-124V/N

Base price: 135 €

Salesprice with discount

Sales price 163 €

Price / kg: